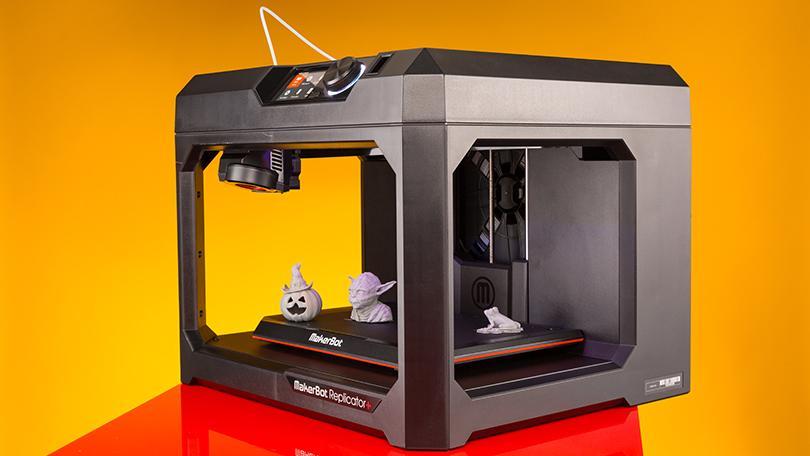

3-D printers are the most important invention that completely transformed the manufacturing industry. Buying a new 3-D printer is a complicated task. These modern printers are quite expensive. There are many kinds of printers each having unique functions and features. Hence there are multiple factors that must be assessed before making the purchase. Otherwise, you will be regretting your decision.

Compare the prices

You can always check the prices online. There are many companies that deliver the product at your doorsteps even on the same day when you order a product. You can also check and analyze the product prices while reading critic reviews.

However, the price depends mostly on the material which is used by the printer in making certain products. Secondly, some printers use high-end technologies like SLM in the making. These powdered materials have become quite expensive for big industries. They have to make thousands of products on a daily basis and cannot afford such expenses. Another drawback of using such high end powdered materials is that they have limited shelf life. Therefore, it is not favorable for a company to store these materials. You can also find some best deals by using dell home office coupons.

How much printing space do you require?

The printing space can be referred to as build volume. You have to decide how much printing space you will be needing before buying a printer. It is not the best approach to choose a printer with a large build volume thinking that it will cater to all your needs. Let’s say it is decided that you will be creating small printed objects. So it will be a useless act to buy a printer will greater build volume.

However, if you ever need to print a large object, you can outsource the project instead of buying another printer. This will a cost-effective approach.

Look for a high-resolution printer

The resolution totally depends upon the nature of the work. If your work includes detailed layering, you should buy a high-resolution 3-D printer. Because high resolution guarantees maximum layering which ultimately leads to the clear and fine print. An architecture agency will be requiring a high-resolution printer because they have to create compact and complex models and cannot compromise on the quality. Similarly, a car manufacturing company creating the interior a car using a 3-D printer will be requiring a high-resolution printer because they are targeting the minimal details.

There are some industries that produce bulky objects using the printer. They can compromise on the detailing because if they increase the layering, it becomes difficult to manage the expenses. If a company makes household items like baskets, cooking utensils, or chairs will not be needing a high-resolution printer as they are making daily use items.

Hence the resolution has a direct effect on the product quality and the features it has to perform.

Keep in mind all the above factors while buying a 3-D printer.

Leave a Reply